A Company with Heart

I like to think of U-Step as a company driven by the heart. Our origin story, which many of you are already familiar with, began with my mother. I created U-Step to give her the security and stability she so desperately needed due to her diagnosis of a rare Muscular Dystrophy Disease called “Charcot Marie Toothe”. We believe that the individualized attention and care to all of our customers is unique and special to U-Step. We’ve found that this not only has created better customer relationships but has also pushed us to innovate our products and grow our company.

When our customers contact us, we listen. They will often explain their unique situation and challenges, we listen and then we do our best to offer them the best solution. Our goal is to make walking easier and safe for everyone, and every bit of feedback, helps us get closer to this goal. Some of our clients come up with some truly “individual” requests (like disassembling a U-Step to make a beautiful purple walker) but many of their needs or suggestions help us create improvements for many.

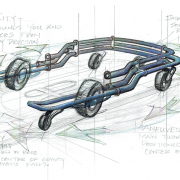

U-Step Platform Model

About ten years ago, a father came in with his son who had suffered a brain injury. The young man had a hard time communicating and relied heavily on the use of a communication keypad. I understood almost immediately that our standard U-Step was not what this young man needed. He benefited from the stability of the U-Step but the standard handlebar model wasn’t going to work. I told him and his father that I think I could design platforms for the young man’s arms if they gave me six months to create it.

After some thought and a few sketches, I ended up ordering large PVC tubing that could be cut in half to make the platforms. I contacted one of my suppliers and asked him to make a few custom parts. After half a dozen attempts, we finally had functional and comfortable platforms. We hired a seamstress to sew custom covers, added foam padding and created custom brake cables. When all was said and done, we invited the young man to come in and test the different models. It made a world of difference for this young man and I knew from that point on, this was a product we needed to offer.

Before mass production, I wanted more feedback on the design from our clients. I worked with three major rehabilitation centers and about twenty-five U-Step users to improve the product for patient treatment. After receiving feedback and making the appropriate changes, we moved on to mass production of the U-Step Platform, which is one of our best selling designs.

Laser Cueing

Over twenty years ago, the U-Step was being prescribed as a fall prevention device at multiple neurological centers for their Parkinson’s patients. Having a background in research, I sent out a survey to our customers to see how they were doing with their U-Step. Overall, people were doing well but only about half reported that the U-Step was helping them with their Parkinson’s freezing (hesitation). Since the U-Step was working well for these individuals in all other aspects, I decided that trying to develop a feature to address Parkinson’s freezing was important.

I began to search for a solution and discovered that a light cue may be an answer to the problem. I started creating a variety of prototypes while working with multiple electrical engineers. I produced a test product that had LED lights in a row of ten which went off in a line – one at a time. It was a total dud. The few neurological centers who tried it with patients found no benefit. I entertained many ideas, even holograms, quickly realizing they were out of the question.

Everything changed when I read an article by Dr. Calahan who spoke about using a laser pointer to project a point on the ground to reduce Parkinson’s freezing. He wrote at the end of his article that it would probably be even better if it was a projected line rather than just a point on the ground. To say I was excited to try this concept is an understatement! I couldn’t wait to see if this could be the answer I was looking for.

We pieced together standard and custom parts to produce a laser-projected line on the ground and quickly realized we now had a solution for Parkinson’s freezing. Dr. Calahan’s theory was correct – a line worked much better! Over the years, we have helped over 20,000 people with freezing by the use of our laser cueing technology. Our new products have been upgraded and have been through many refinements to improve their effectiveness and ease of use. A year after production, I met with Dr. Calahan and I showed him the product – and he said, “This is my product! I am glad someone did it!”

Physicians have science and information on their side, but most are focused on treating patients and do not have the time or interest to create products – which leads to our next story.

LaserCane

Jane Wright, who ran a Parkinson’s Information and Referral Center, asked me if I could make a Laser cane. She mentioned that a few Parkinson’s specialists at the University of Pennsylvania had played around with the concept but were unable to make the actual product. Of course, we were up to the challenge.

One of the most challenging aspects was making a custom switch that could handle hundreds of thousands of presses. The activation switch located at the bottom of the cane, is activated with each step a person takes – which quickly adds up into the tens of thousands. Commercial switches are not designed for this high frequency of use, so I realized that we needed to make a super heavy duty switch for our unique application.

This is quite a stretch for a guy with a marketing degree but I worked with a machinist and after a number of tries we figured it out. We refined the product to make it super reliable, including the ability to withstand a fall, and to be weatherproof – which was a challenge in-and-of itself. After releasing the LaserCane, a customer came into our offices with his LaserCane. He reported that he had accidentally dropped his LaserCane off the tenth-floor balcony of his apartment. It landed tip-first and he said it bounced up about three stories on the rebound before crashing to the ground. Frantic, he went down to retrieve it and believe it or not, it still worked.

Over the years, our company has changed and evolved to fit our customer’s needs. I’ve compiled these stories to show that U-Step is not a one-size-fits-all company. We listen to our clients. Just as one question in a crowd can help many, one customer request can inspire a major product change that will benefit many users. So we pay attention, take on challenges, and create durable products that improve the lives of thousands of patients.

Leave a Reply

Want to join the discussion?Feel free to contribute!