The Journey from Prototype to Production: Part 2

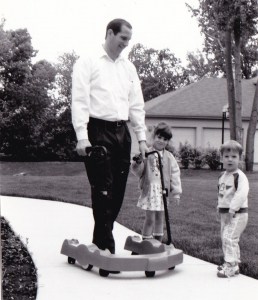

After designing the first U-Step, I decided to continue on the journey to develop a production version. Easier said than done! The original U-Step design had two major drawbacks: it was heavy and it was very expensive to produce. If I was going to try to make this for other people, I would have to come up with a different design.

I was introduced to Mario Braun, a young man who was fresh out of Industrial Design school. We decided to work together on creating a new version of the U-Step. We settled on an aluminum tubular construction base frame covered with a thermo-formed cover.

This unit was one setup over a prototype and had many mechanical shortfalls. Our goal was to get it into good working shape in order to display it at a local rehabilitation conference where we had rented an exhibit booth. I remember that the folding mechanism wasn’t working – the handlebars were wiggling back and forth. (At that point, I learned the limitations of aluminum for strength!) We ended up jerry-rigging the handlebars with wooden shims so they stayed in the upright position and would just tell people it folded without showing it!

This unit was one setup over a prototype and had many mechanical shortfalls. Our goal was to get it into good working shape in order to display it at a local rehabilitation conference where we had rented an exhibit booth. I remember that the folding mechanism wasn’t working – the handlebars were wiggling back and forth. (At that point, I learned the limitations of aluminum for strength!) We ended up jerry-rigging the handlebars with wooden shims so they stayed in the upright position and would just tell people it folded without showing it!

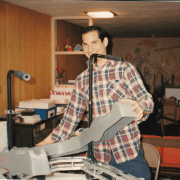

We managed to get the unit in reasonable working condition and went to exhibit it at the conference where we set up different surfaces – cement, carpet, and tile – where people could try it. Things were going well and we were getting a lot of good feedback on the product. That is until one strong therapist squeezed the hand brake and snapped the brake cable. We immediately knew from the sound that we had a problem. The unit could no longer be shown in that condition. Mario and I had a quick pow-wow and decided to take the unit outside and try to fix it. Without trying to draw too much attention and with a tool kit in hand, we went outside to fix it. (Above is a picture of that challenging moment.) We got down on our hands and knees in the hot sun and got it back in working order in about fifteen minutes.

We managed to get the unit in reasonable working condition and went to exhibit it at the conference where we set up different surfaces – cement, carpet, and tile – where people could try it. Things were going well and we were getting a lot of good feedback on the product. That is until one strong therapist squeezed the hand brake and snapped the brake cable. We immediately knew from the sound that we had a problem. The unit could no longer be shown in that condition. Mario and I had a quick pow-wow and decided to take the unit outside and try to fix it. Without trying to draw too much attention and with a tool kit in hand, we went outside to fix it. (Above is a picture of that challenging moment.) We got down on our hands and knees in the hot sun and got it back in working order in about fifteen minutes.

We finished the exhibit with the feedback we needed, knowing that we had a long way to go to refine this product. However, we had taken one step forward by switching to a tubular design.

We finished the exhibit with the feedback we needed, knowing that we had a long way to go to refine this product. However, we had taken one step forward by switching to a tubular design.